Tunnel Lights

HOUSING

- The housing of the light is made from stainless steel V4A 1.4571 and may be surface treated with electrochemical polishing after manufacturing.

- The frame (cover) of the light is equipped with rotating locks, which are adjustable and secured with a safety catch to prevent opening. The light can be opened without the use of tools, and the cover can be flipped open to either side.

- The glass of the light is 6 mm tempered, glued into the frame. In the event of breaking, it shatters into small fragments. The seal is made in two rows, inserted into the frame of the light, with the inner seal positioned at a higher level than the outer one (viewed from the bottom).

- The type of cable entries is determined by the customer.

MOUNTING

- The light is mounted using four brackets (two on each side), which are designed with elongated holes for easier installation. These are attached either to a substructure or directly to the tunnel ceiling. Standard material is 1.4571 or upon request 1.4529, or another material that meets class 1 requirements.

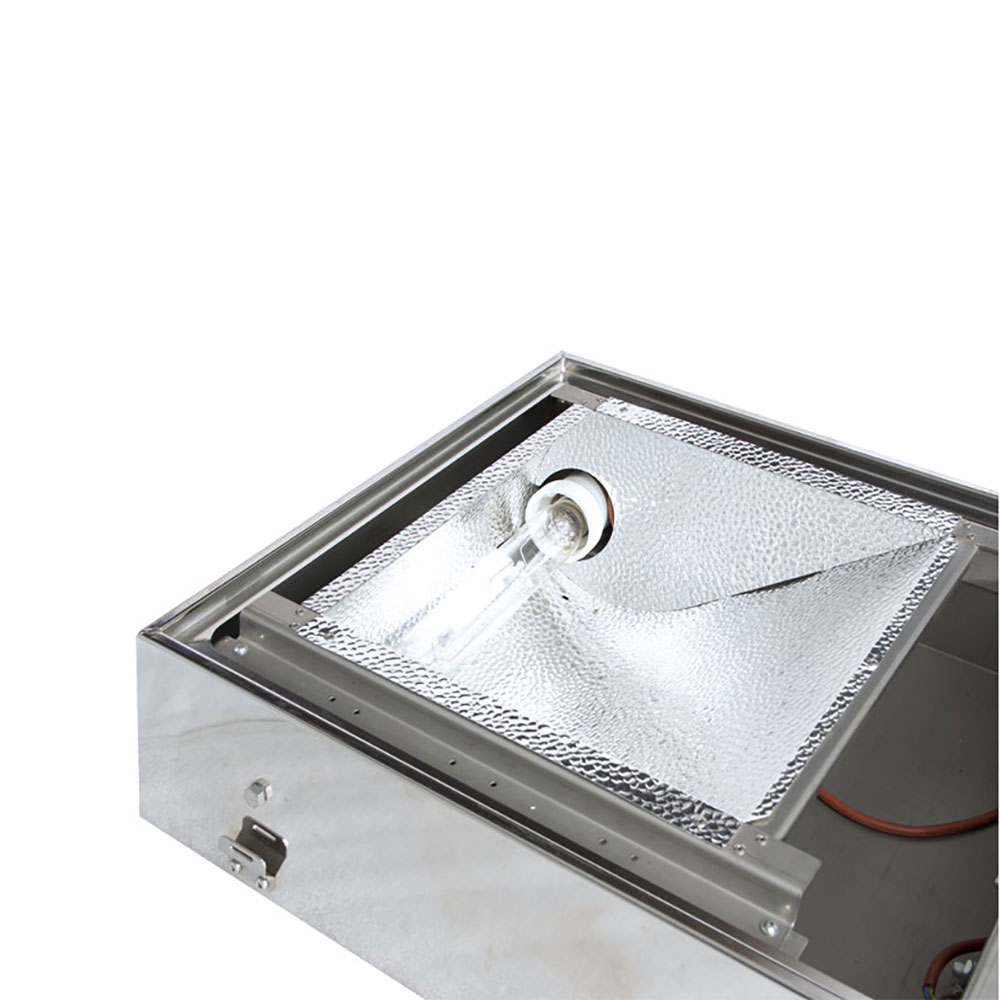

REFLECTORS

- The housing of the light is designed to be universal for multiple types of reflectors. Entrance lights can be equipped with the following reflectors:

• LIV 905 Asymmetric Reflector (efficiency 76%)

• LIV 401 Asymmetric (efficiency 72%)

• LIV 411 Asymmetric (efficiency 86%) - All reflectors can rotate 90° and are fixed by simple insertion. Drive-through lights are either symmetric with 1 reflector or with two reflectors.

ELECTRICAL SPECIFICATIONS

Electronics Carrier

- The carrier holds the ballast, igniter, capacitor, power compensation, and the control board for the light signaling.

- The indication board can safely and reliably signal a malfunction, allowing the issue to be identified even before intervention, which positively impacts maintenance costs.

- The carrier is designed to be removable, so in case of malfunction, it can be fully replaced by disconnecting two connectors.

- The connection terminals are quick-connect spring-loaded – Weidmuller or Phoenix.

Power Reduction

- The power reduction of the light is based on calculations for the specific project and tailored to the customer’s requirements.

- The reduction can be applied to all levels with Cos Phi > 0.95.

Technical Details

- Protection Class: IP 66

- Class: I

- Light efficiency: 72-86%

- Electrical connection: 230VAC; 5A; 50 Hz/70-400W

- Weight: 25 kg

- Thermal test: 200°C for 30 minutes.