Problems that can occur during sheet metal bending

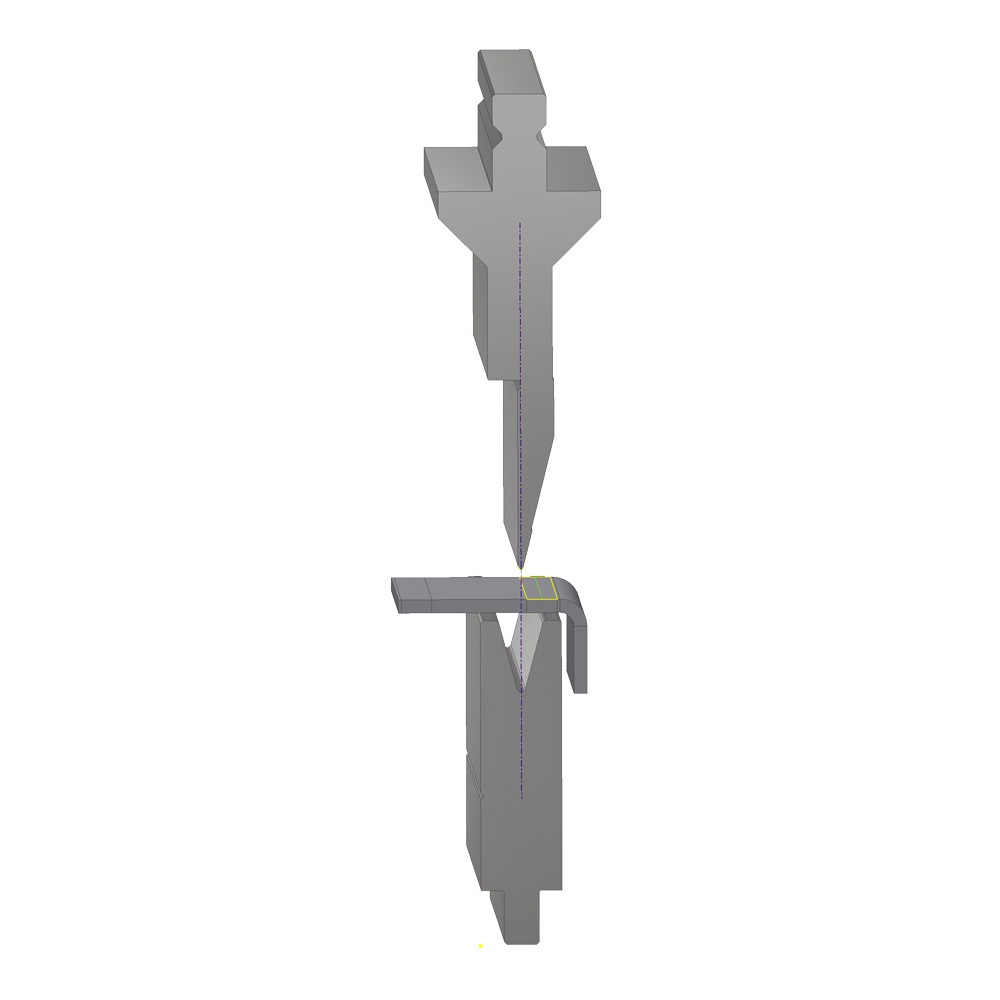

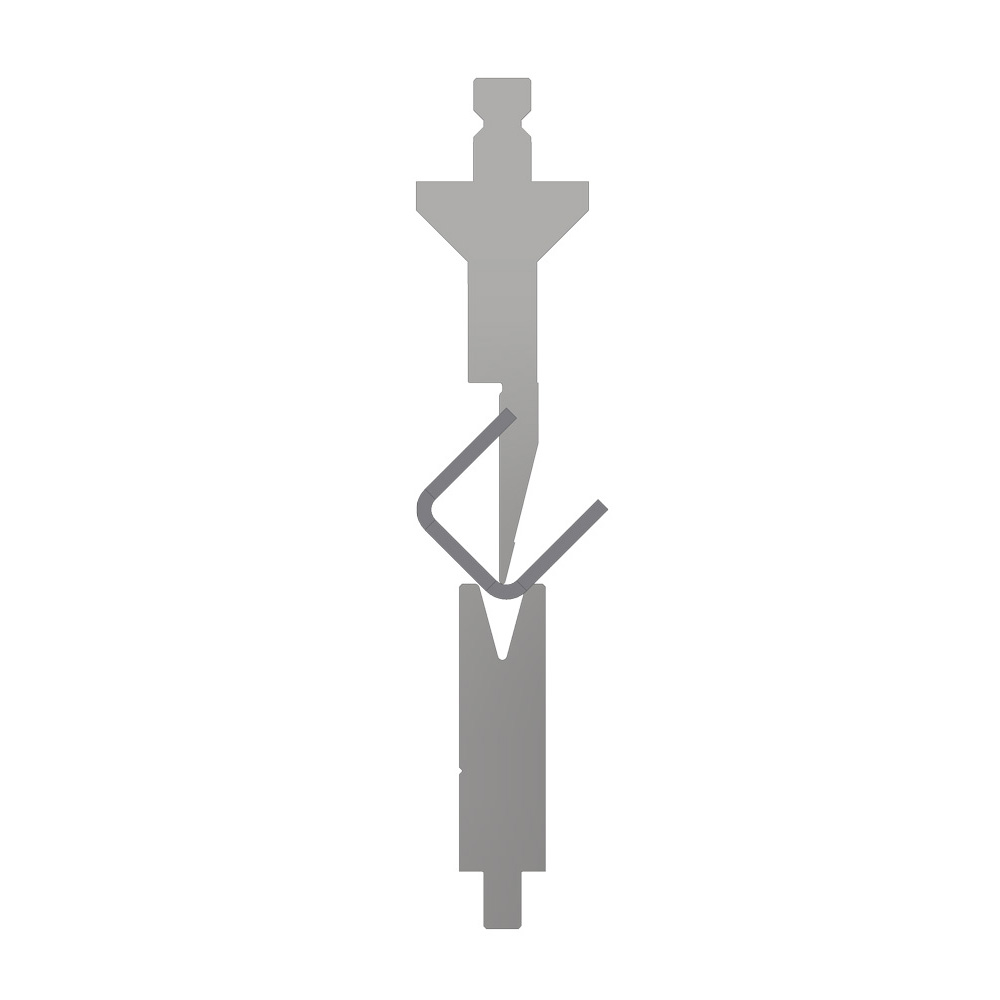

TOO SHORT ARM LENGTH / TOO SHORT BEND

If the bending arm is too short, one side of the sheet metal part will not be placed on the bending tool. Thus, the metal part cannot be produced. The same applies if two Z-shaped bends are too close to each other.

Solution: The arm must be extended, or the Z-shaped bends must be moved. Since the minimum arm length depends on the tool used, the current value must be checked according to the matrix size and sheet thickness in the 90° iron bending table, which can be found here.

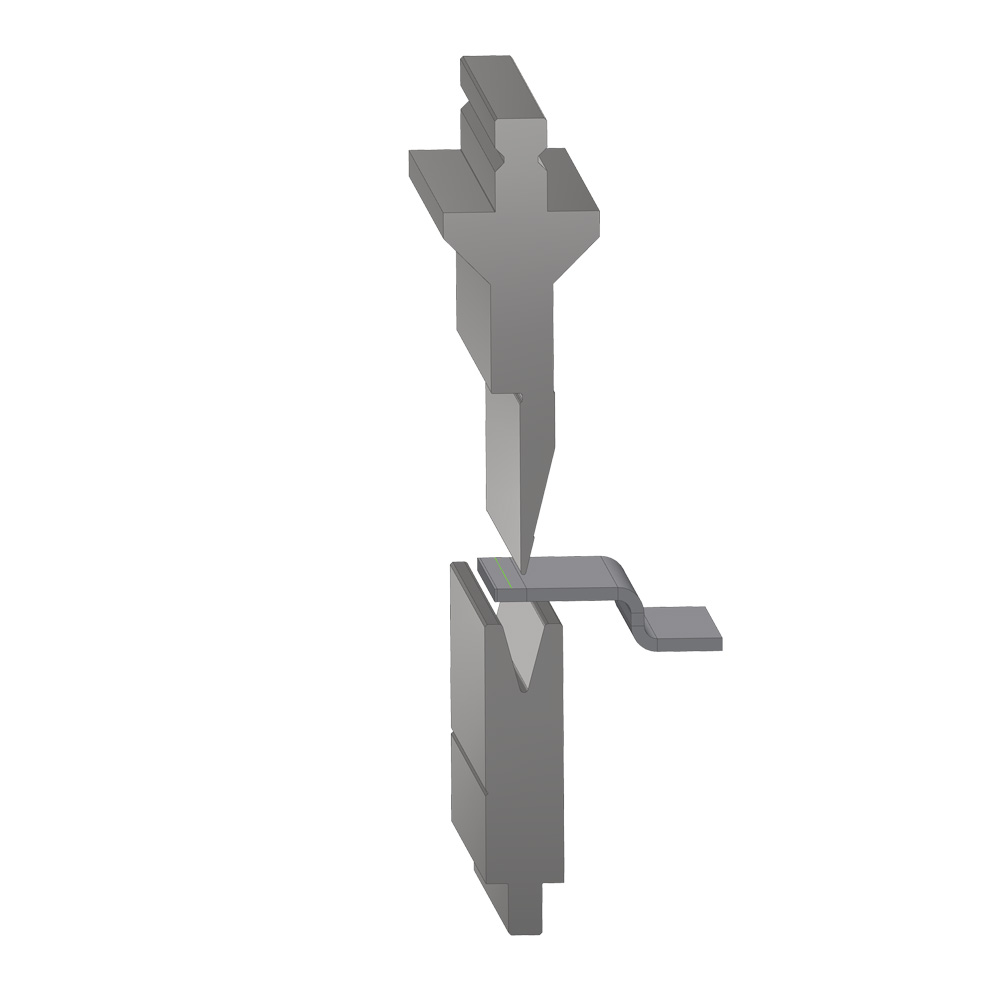

U-PROFILE / BOX

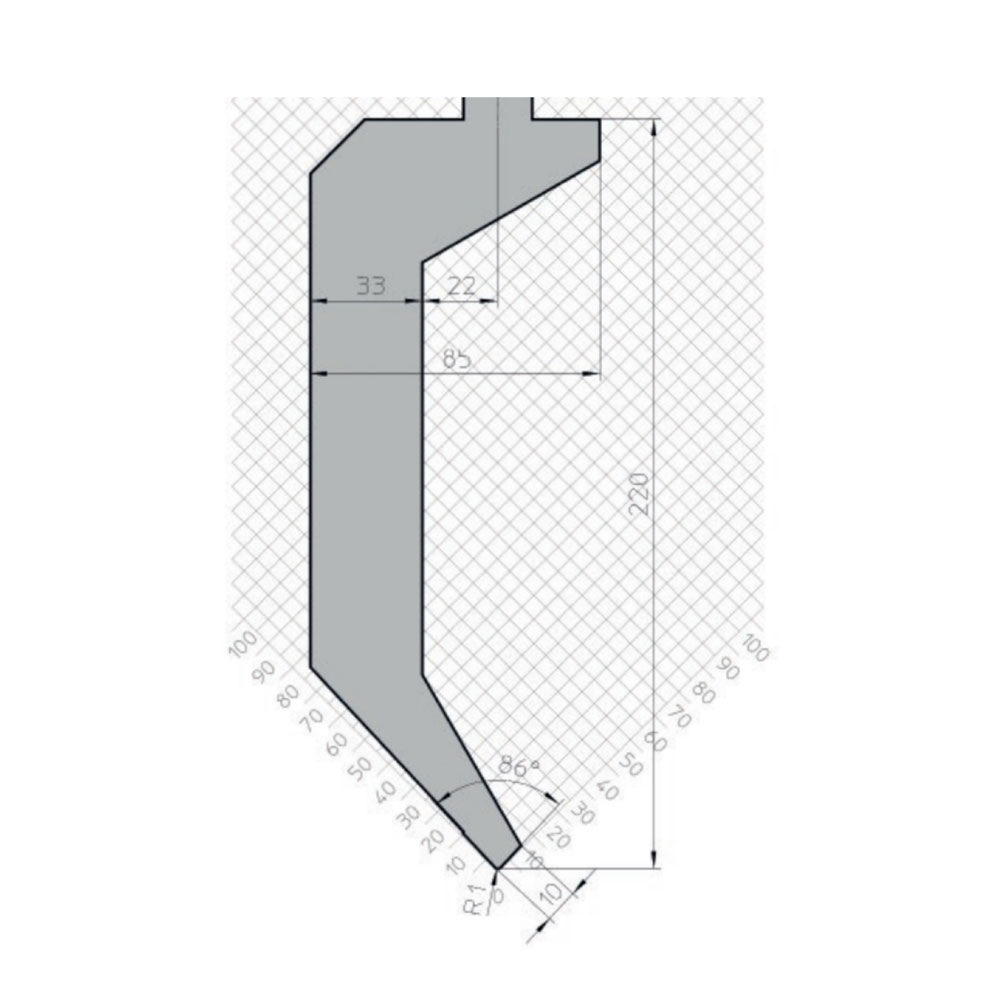

U-profiles or boxes with sides that are too long relative to the base sometimes cannot be manufactured. The component’s sides collide with the tool during bending, or with larger constructions, with the bending machine. Special tools exist that allow slightly longer sides to be produced. Collision with the tool or machine is a typical issue when producing closed profiles.

Solution: If possible, shorten the profile arm — shortening just one is sufficient. If the longer arm is bent first, it will not collide with the tool during bending. Instead of shortening the foot, the base can also be extended.

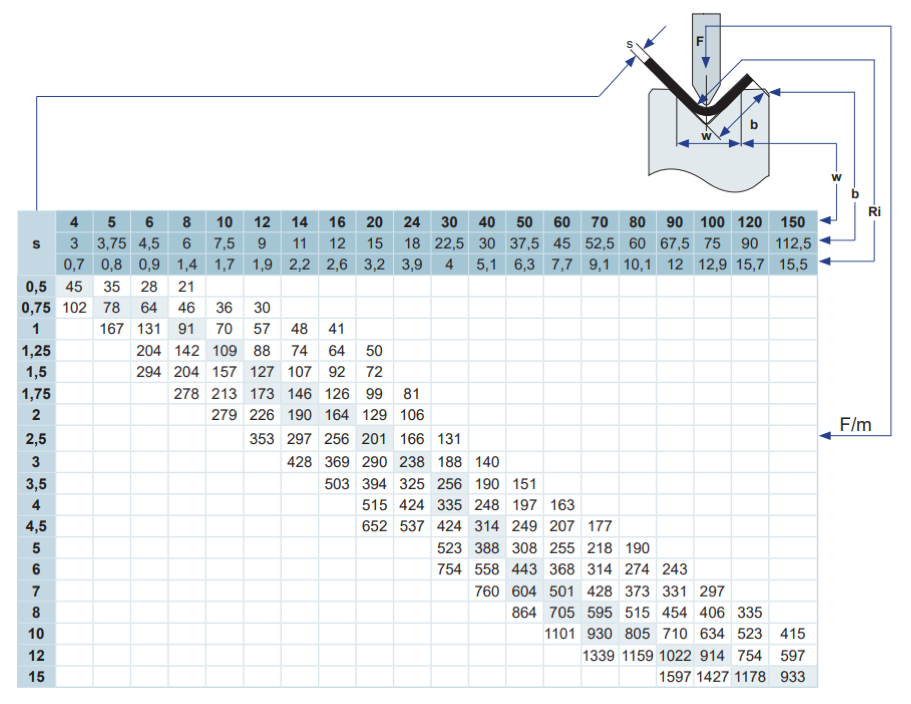

IRON BENDING TABLE AT 90°

S = material thickness

W = matrix width

b = minimum bend length

Ri = approximate internal radius

For example: 2 mm iron can be bent on a matrix of 10, then the minimum bend length must be greater than 7.5 mm, and the pressure will be 279 kN/m.

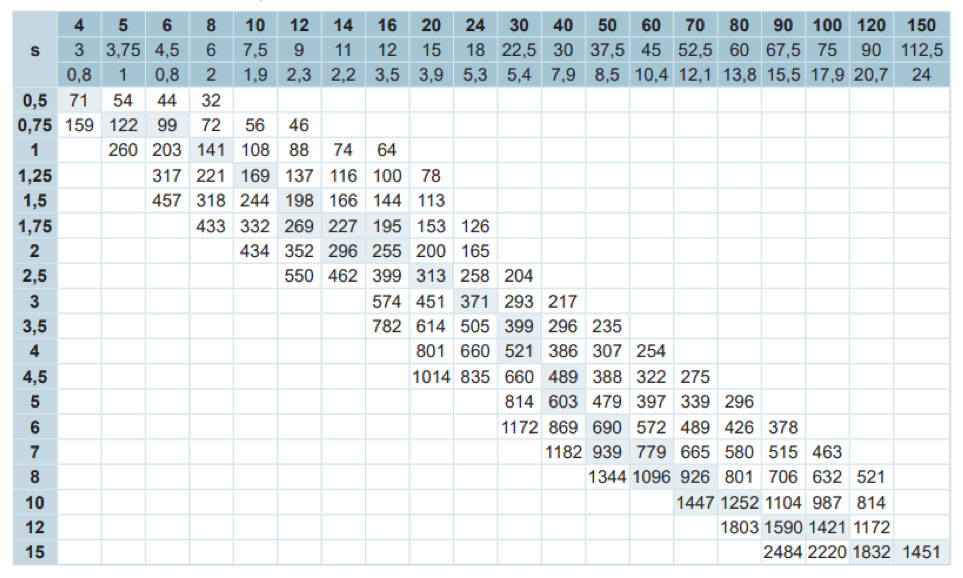

STAINLESS STEEL BENDING TABLE AT 90°

S = material thickness

W = matrix width

b = minimum bend length

Ri = approximate internal radius

For example: 2 mm stainless steel can be bent on a matrix of 10, then the minimum bend length must be greater than 7.5 mm, and the pressure will be 434 kN/m.

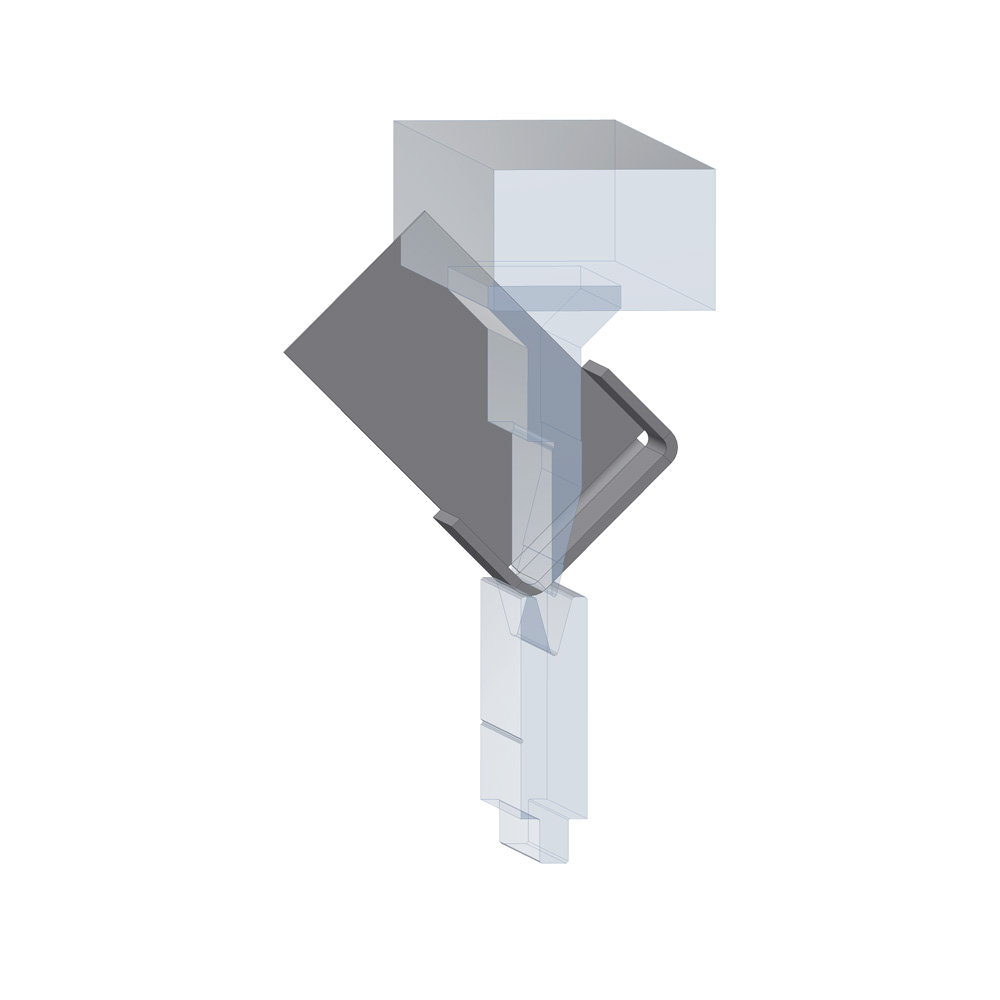

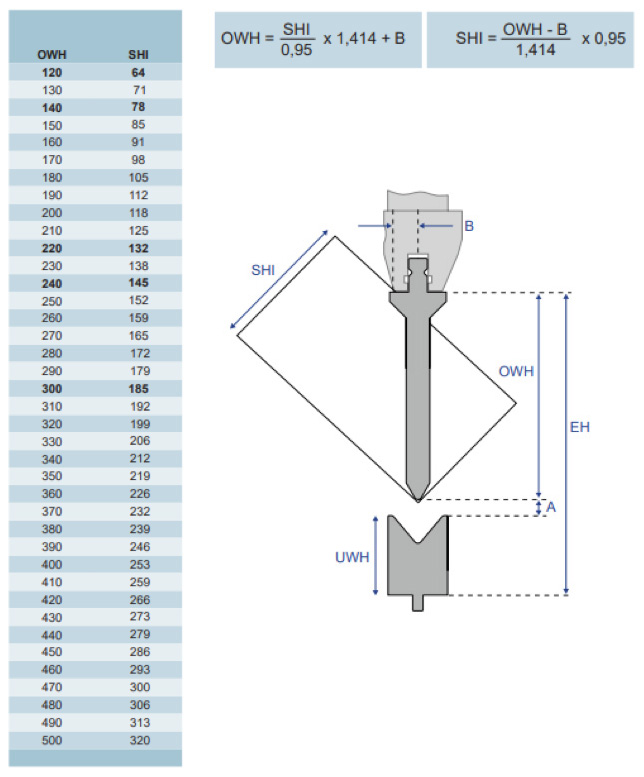

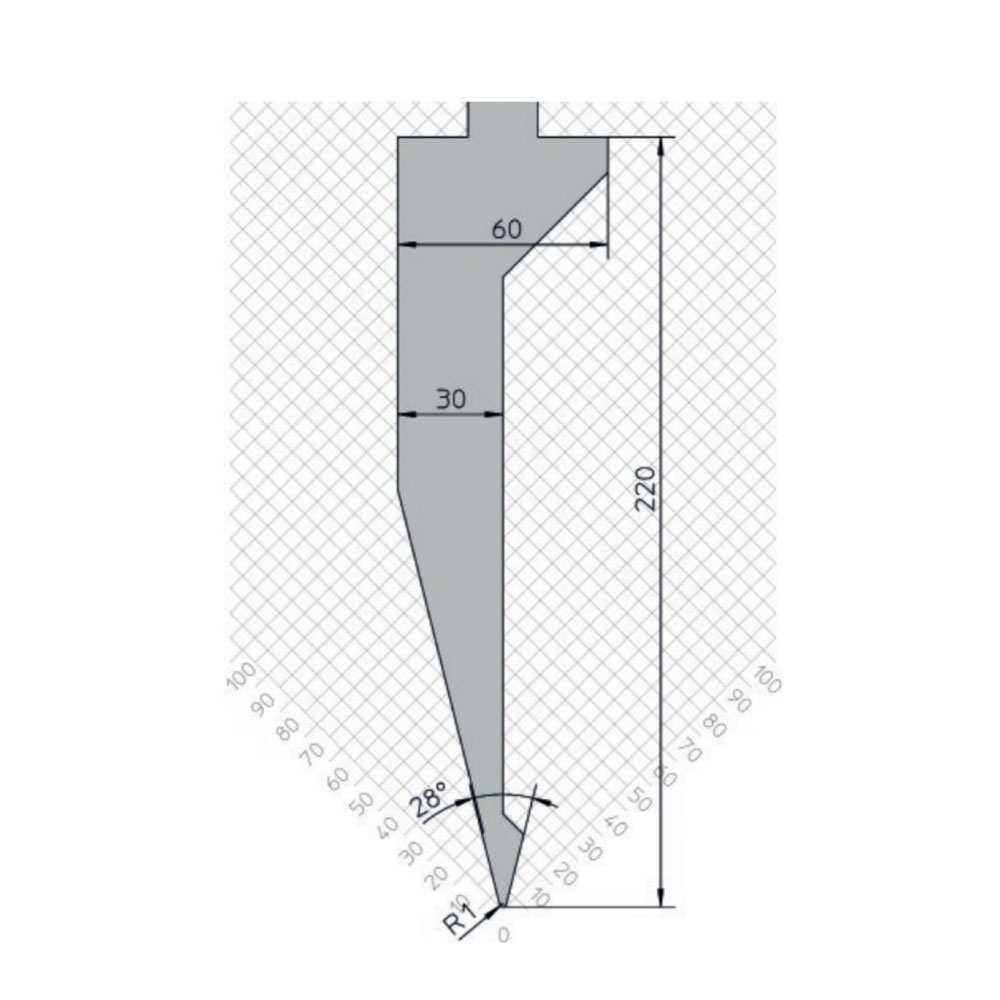

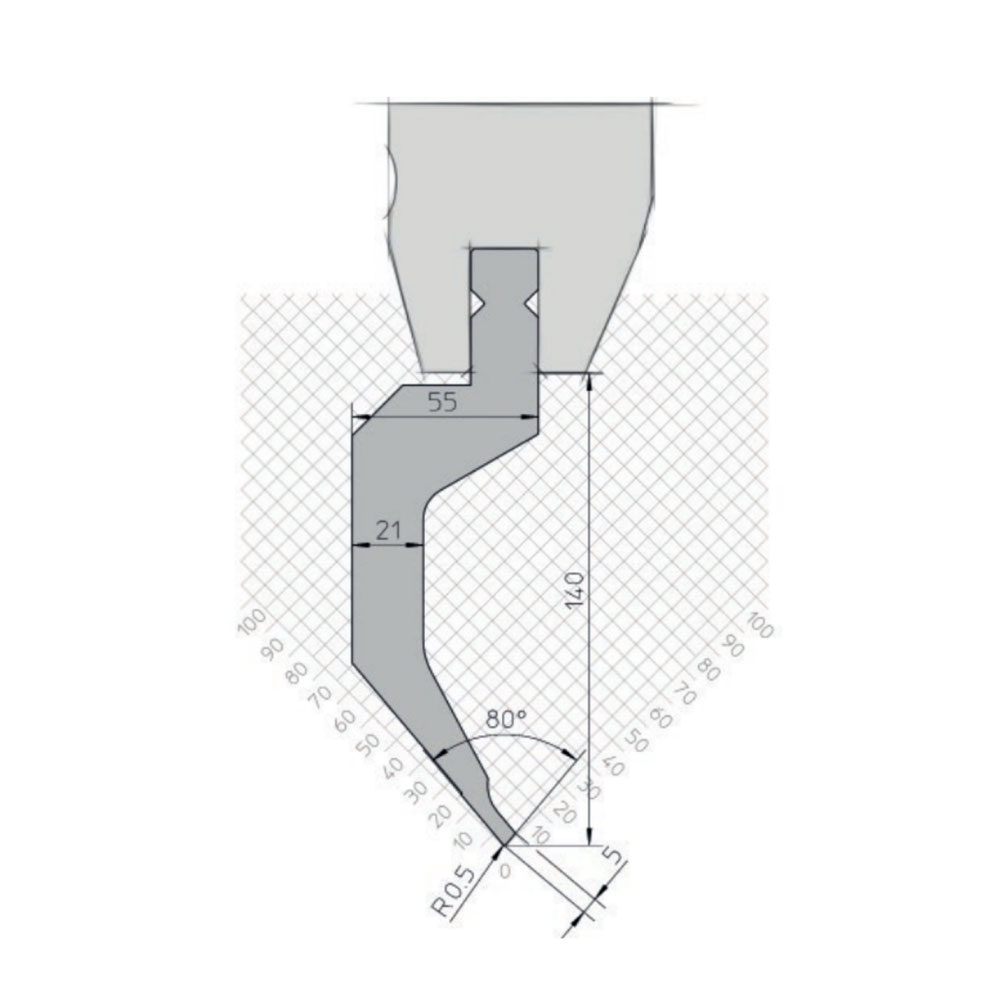

CALCULATION OF THE MAXIMUM HEIGHT OF THE BOX

The maximum height of the box is primarily defined by the machine’s mounting height.

The mounting height is the maximum distance between the lower edge of the upper tool holder and the upper edge of the lower tool holder.

B = top edge to the center of the ram

A = residual tool path height

SHI = internal height of the box

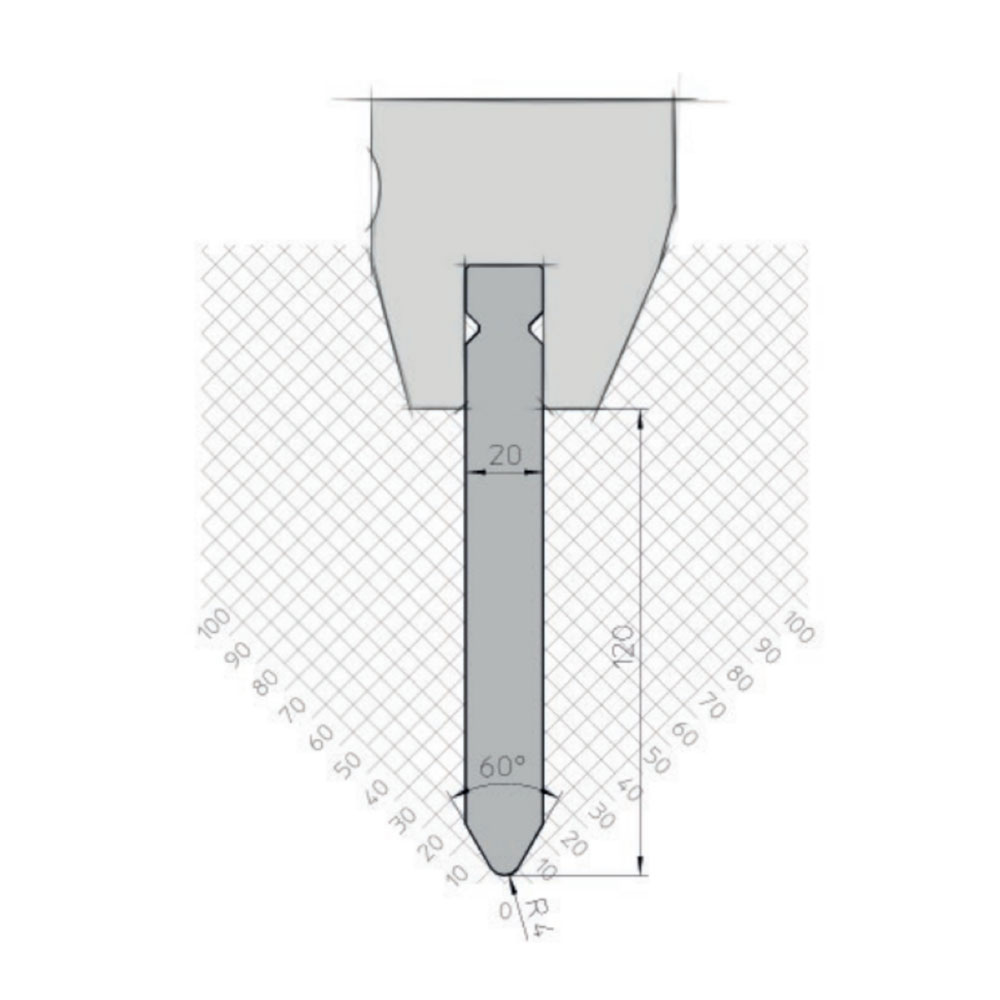

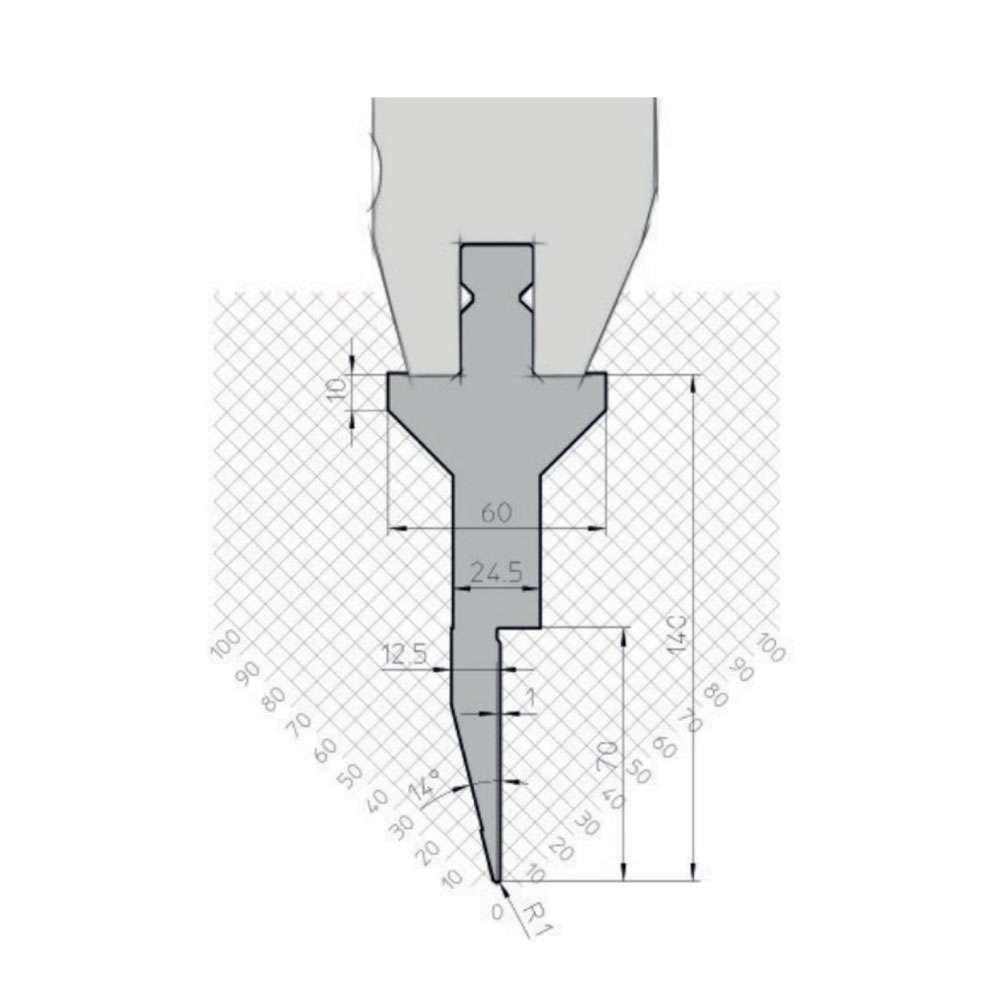

OWH = upper tool height

UWH = lower tool height

EH = mounting height